Key points

The research focus of the Biomechanics and Kinematics Department is on the functional testing of orthopaedic implants and joint kinematics. In close cooperation, engineers and physicians conduct interdisciplinary research into artificial joint replacement with a wide range of clinical issues. The Department offers a range of services and procedures and has built up a broad spectrum of methods in numerous projects over the years.

You are welcome to contact us with your questions. The Biomechanics and Kinematics Department of the LBB offers an open portal for scientific cooperation or contract research.

Dr. Bastian Welke

Phone: +49 (0)511 5354 652

Fax: +49 (0)511 5354 875

E-mail: welke.bastian@mh-hannover.de

Services & procedures

- Joint kinematics

- Rigid body analysis

- Migration determination

- Shoulder - surgical techniques, endoprostheses, osteosynthesis implants

- Spine - dynamic implants, spondylodesis implants, intervertebral disc prostheses, kyphoplasty

- Knee - endoprostheses, functional permanent loading

- Hip

- Creep indentation

- Strength test

- Shoulder

- Spine

- knee

- Hip

- Knee joint components

- Hip joint components

- Multi-body simulation - The AnyBody Modeling System

- Finite element analysis - ANSYS

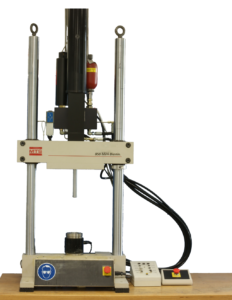

Testing machines

Serial six-axis robot KUKA KR16-2 with KR C4 controller

- Force and torque control

- Six-component sensor

- Max. Load: 16kg

Kinemator

- Seven servo-hydraulic actuators

- Maximum force per actuator: 3000N

- Force control

Applications

- Functional joint and implant testing

- Hip

- Shoulder

- Knee

- Spine

Technical data

- Maximum axial load (tension/compression): 15kN

- Maximum torque: 100Nm

- Hydraulic unit pressure: 270 bar

- Maximum actuator travel: 150mm

- Total rotation of actuator: 270°

- Various force transducers: 500 N, 2.5 kN, 15KN/150Nm

Application range

- 3- and 4-point bending

- Testing of long bones

- Testing of implants (intramedullary nails, osteosynthesis plates,...)

- Fatigue testing of entire constructs

- Fatigue strength and load-bearing capacity of implants for osteosynthesis

- Testing of soft tissue (tendon rupture,...)

Technical data:

- Maximum load: 100 kN

- Test temperature: -70°C to +350°C

- Frequency range from 1 to 10 Hz

- Distance between the clamps 562 mm

- Drive unit hydraulic system

Application:

- Tension, compression, bending

- 3- and 4-point bending

- Testing of long bones

- Testing of implants (intramedullary nails, osteosynthesis plates,...)

- Fatigue testing of entire constructs

- Fatigue strength and load-bearing capacity of implants for osteosynthesis

- Testing of soft tissue (tendon rupture,...)

- Fatigue tests

Technical data

- Maximum test load: 10kN

- Maximum transverse speed: 800mm/min

- Two load cells: 200N and 10kN

Application

- Tensile tests of soft tissue (tendons, heart valves,...)

- Confined compression test of cartilage tissue and constructs

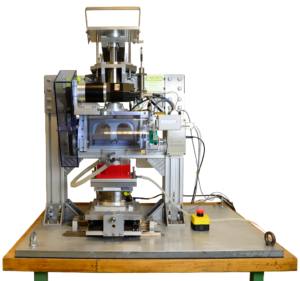

Simulation of the knee movement

- Imitation of the typical knee joint load under a rolling-sliding movement

- Standardized test method (based on ASTM F1715-00, ASTM F2026-06, ISO 14243-2)

- Simplified geometries of the knee implant components: Base plate (tibia) and cylindrical counter body (femur)

- Axial force of 700N (simulated single-leg stance)

- Replacement synovial fluid tempered to 37°C

Wear test

- Determination of the material loss of implant materials

- Representation of wear behavior by means of gravimetric measurement

- Long-term wear measurements of different material pairings

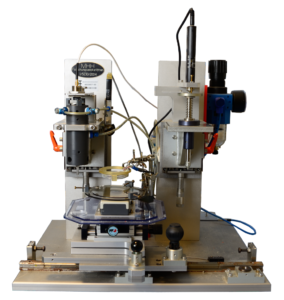

Simulation of the knee movement

- Imitation of the typical knee joint load under a rolling-sliding movement

- Simplified geometries of the knee implant components: Biconcave base plate (tibia) and biconcave cylindrical counter body

- Axial static load

Replacement synovial fluid or lapping agent

Wear test

- Determination of the material loss of implant materials

- Representation of wear behavior by means of gravimetric measurement

- Long-term wear measurements of different material pairings

Measured variables:

- Determination of the biomechanical properties of cartilage tissue - and constructs

- Determination of the thickness of cartilage tissue and constructs

Areas of application:

- Cartilage tissue

- Cartilage constructs

- Cartilage regeneration rate

- NDI Polaris P4

- NDI Optotrak Certus

Generator output:

- Conduction: 40kV to 110kV/0.2 to 6mA

- Absorption: 40kV to 110kV/20mA

- Operating frequency: 20Hz

Max. Operating data:

- Transmission: 100kV/0.2-6mA

- Recording: 110kV/20mA

- Exception time: 0.1 to 4 seconds

X-ray control area:

- Double focus standing anode tube

Image intensifier tube:

- 17/10 cm or 23/15 cm, caesium - iodide

- Magnification: 1.5x

Fluoroscopy grid:

- Pb 8/1 40

Technical data

- Measuring resolution/readability: 0.01mg

- Reproducibility <±mg 0.015/0.025

- Linearity deviation <±mg 0.1

- Max. Range: 230g

- Measuring time (typical): 8s

- Operating temperature range +10 ... +30 °C

- Fully automatic draft shield

- Integrated electrostatic eliminator to neutralize interfering electrostatic charges (ionizer)